When you need a low quantity of custom parts machined or simply needing a single replacement our manual machines are up to the task. We have very skilled manual machinists that are well versed in lathe, milling, and broaching operations. Reversed engineered parts for breakdown repairs are most commonly manufactured in our manual machine shop.

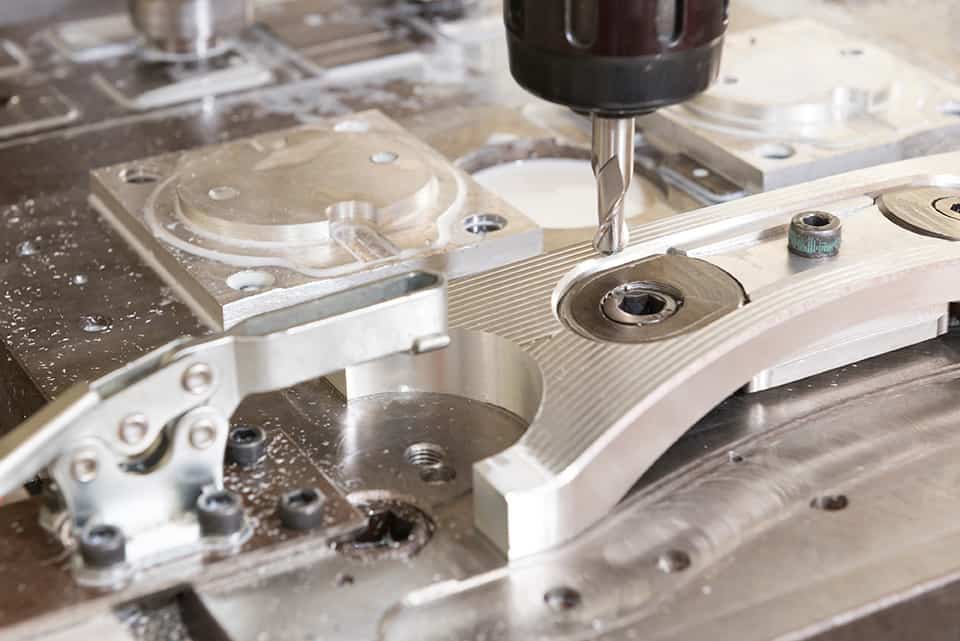

Our advanced CNC machining capabilities handle both high-volume production runs and complex geometries with precision. Our expert machinists leverage state-of-the-art equipment for exact programming, setup, and operation to deliver components that meet your exact specifications every time. Through rigorous quality control and technical expertise, we ensure measurable precision for your most demanding industrial applications.

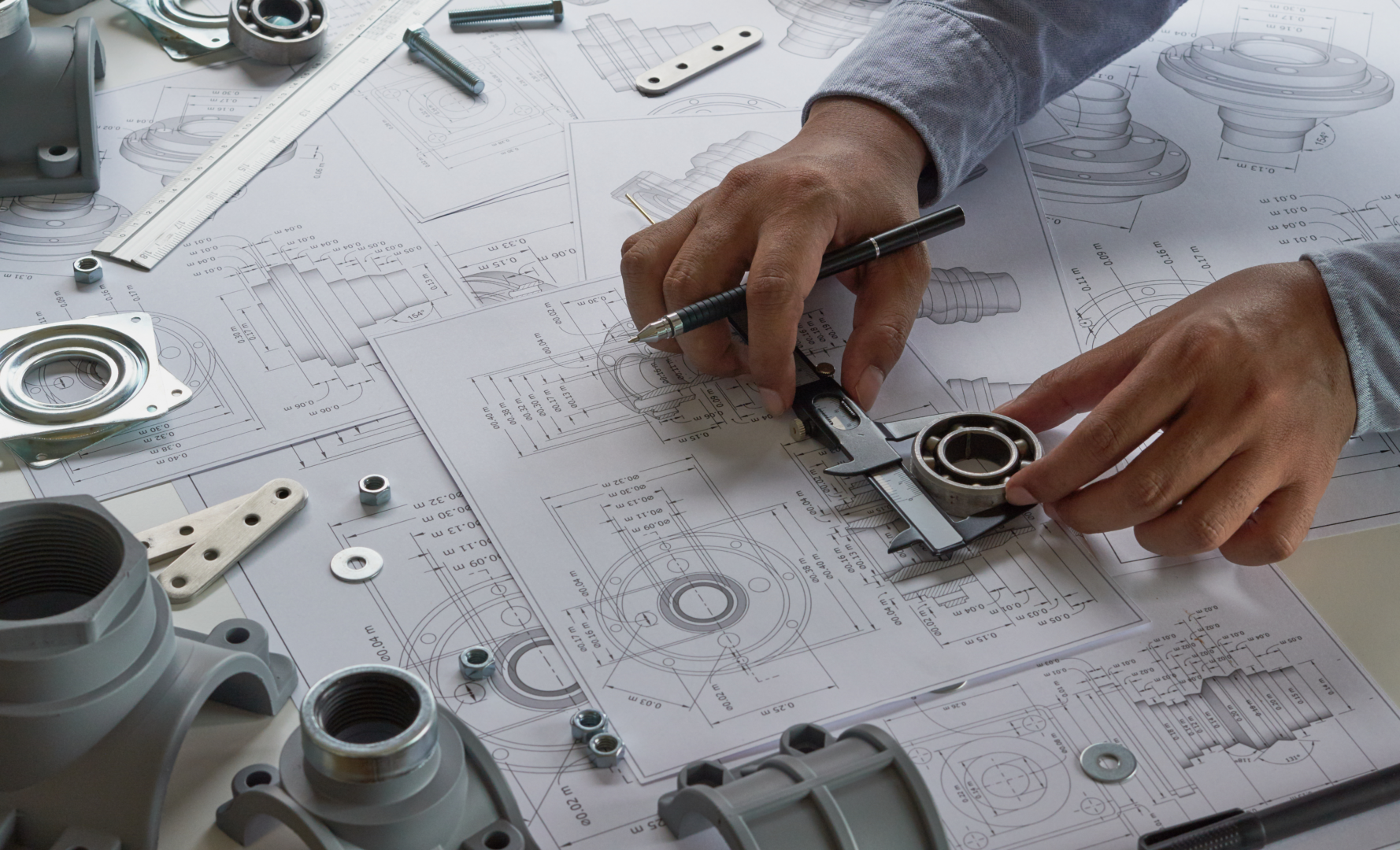

Our comprehensive metal fabrication solutions are designed to meet the exact specifications and unique challenges of your industrial applications. With cutting-edge equipment and skilled technicians, we handle everything from simple components to complex assemblies with precision and attention to detail. Our team works closely with clients to understand their requirements, ensuring each fabrication project meets the highest standards of quality and functionality while maintaining cost-effectiveness.

Our expert maintenance team delivers maximum equipment uptime through systematic diagnostics and precision repairs. Using advanced testing equipment, our certified technicians swiftly identify and resolve issues, while our 24/7 emergency response capability ensures immediate solutions for critical breakdowns. With extensive in-house inventory and proven protocols, we manufacture and deliver replacement components to exact specifications, maintaining production continuity even when standard supply chains are unavailable.

Expert CNC and manual machining capabilities for complex parts

Comprehensive range of industrial machining tools and technology

Experience working with diverse metals and industrial materials

Handling both custom one-off parts and high-volume runs

Round-the-clock emergency machining services when you need them

Our facility features advanced CNC lathes, mills, and machining centers capable of handling precision parts with complex geometries.

We work with a wide range of materials including various metals (steel, aluminum, brass, copper), plastics, and specialty alloys. Our expertise covers both standard and exotic materials based on your specifications.

Yes, we offer 24/7 emergency service for critical operations. Our team specializes in reversed engineered parts for breakdown repairs.

Each project includes comprehensive quality documentation with detailed inspections and necessary certifications. Our quality control system includes multi-point inspections, advanced testing equipment, and documented procedures.

Yes, we’re equipped for both custom one-off parts and high-volume production runs. Our manual machining is ideal for low quantity custom parts, while our CNC capabilities handle larger production needs.

We provide comprehensive machining services including manual turning and facing, vertical milling, horizontal boring, surface grinding, and custom threading and gear cutting operations.

We serve diverse industries including manufacturing, automotive, aerospace, food processing, pharmaceuticals, and general industrial applications. Our versatile capabilities allow us to meet requirements across multiple sectors.

Turnaround times vary based on project complexity and current workload. Standard projects typically complete within 1-2 weeks, while rush orders and emergency services are available for urgent needs.

Yes, our engineering team can assist with design optimization, material selection, and manufacturing process recommendations to ensure your parts meet both functional requirements and cost objectives.

Our facility maintains industry-standard quality certifications and follows strict quality control procedures. We can provide detailed documentation including material certifications, inspection reports, and dimensional verification.

Ready to experience precision industrial machining? Contact our team to discuss your requirements or schedule a facility tour.