Hydraulic cylinders are crucial components in industrial machinery. Even minor damage can reduce lifting power, cause erratic movements, or create fluid leaks. Our expert repair services restore cylinders to OEM specifications, ensuring peak performance. We provide:

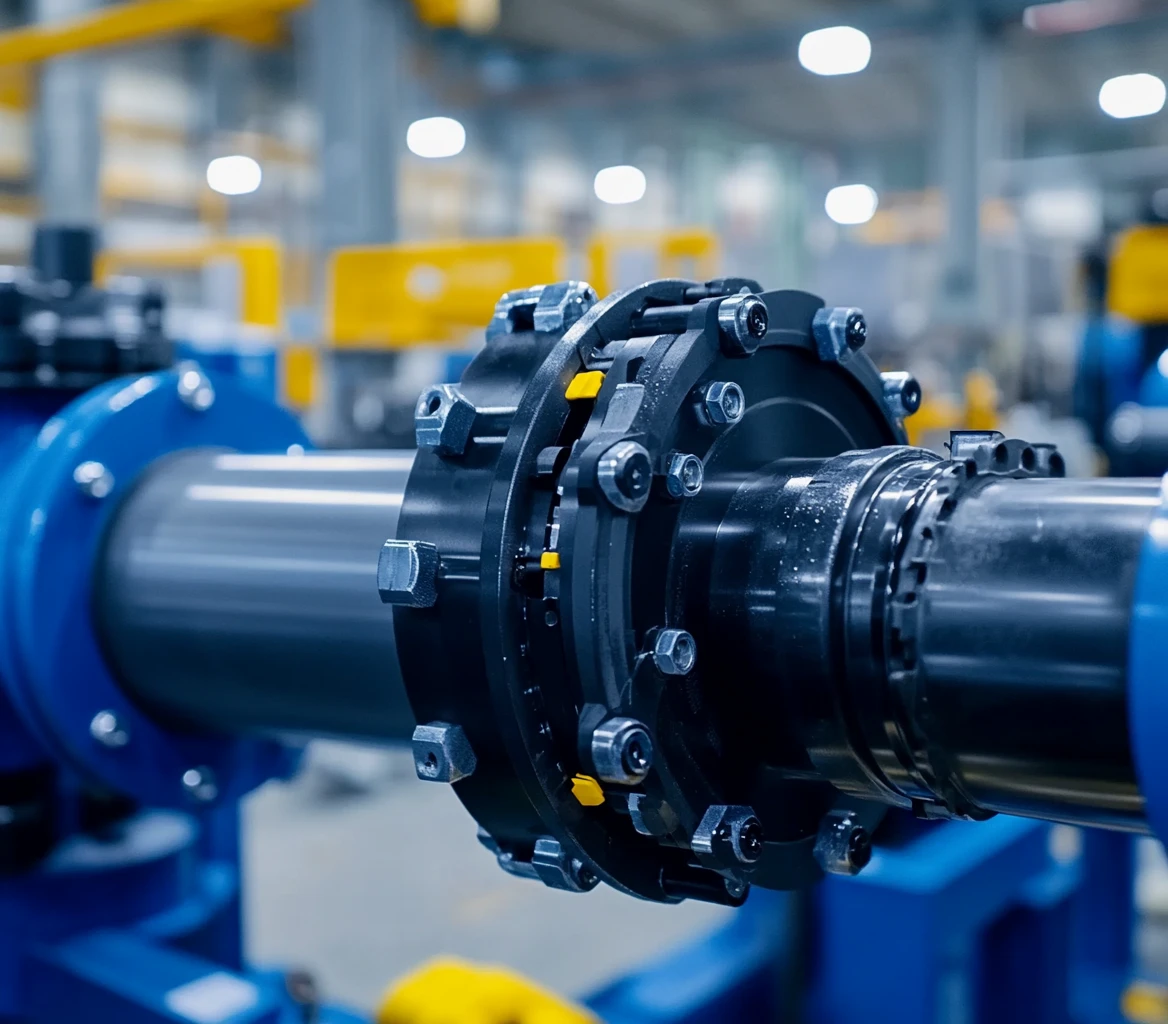

Hydraulic pumps are essential for maintaining system pressure and efficiency. When a pump fails, it can cause inconsistent power output, overheating, and waste energy. Our technicians thoroughly diagnose, repair, and test hydraulic pumps to ensure reliable performance and stable pressure. We service all major hydraulic brands including Denison, Parker, Vickers/Eaton, and Sauer Danfoss. We repair:

Professional hydraulic repairs ensure your system maintains peak performance through consistent pressure, smooth movement, and optimal efficiency. When hydraulic valves fail, they can lead to erratic system performance, pressure loss, and actuator problems. Ferguson Industrial specializes in expert valve repair and replacement services to restore your system’s control and efficiency. Our process includes:

From minor fixes to complete overhauls, our comprehensive HPU repair services restore hydraulic power units to peak performance. As the heart of your system, a properly functioning HPU is crucial for maintaining pressure and flow. When malfunctions occur, they can lead to costly production stoppages and safety risks, which is why Ferguson Industrial offers full-service repair and custom rebuilding to keep your operations running smoothly while minimizing downtime.

Ferguson Industrial provides 24/7 emergency hydraulic repair services with a rapid response team that diagnoses and fixes issues onsite. We minimize operational downtime by prioritizing quick equipment restoration through swift diagnostics, immediate component replacements, and efficient repairs—getting your systems back to peak performance fast. Our emergency repair capabilities include:

Our preventative maintenance programs include:

Minimized downtime with quick, efficient repairs.

Skilled in repairing all types of hydraulic components.

Flexible repair options based on your needs.

Rebuilt components that match or exceed original specs.

Immediate assistance when failures occur.

Learn more about our repair process, common hydraulic issues, and how to prevent failures.

Signs of hydraulic cylinder failure include fluid leaks, sluggish movement, weak lifting power, or erratic operation. If you notice any of these, a repair may be necessary.

Yes. We repair hydraulic pumps, valves, cylinders, and power units from all major brands, including Parker, Vickers/Eaton, Denison, Sauer Danfoss, Bosch Rexroth, and more.

Standard repairs take a few days, while custom rebuilds may take one to two weeks. Emergency repairs are handled immediately.

Yes. Our mobile service team offers onsite diagnostics and repairs, including hose replacement, system troubleshooting, and minor component repairs.

If a component is beyond repair, we offer new replacements or custom-built alternatives to match your system’s exact specifications.

Hydraulic pumps and valves should be inspected annually, with maintenance scheduled based on workload. Heavy-use systems may require quarterly servicing.

Pump failures often result from fluid contamination, excessive heat, improper pressure settings, or worn seals and bearings. Regular maintenance prevents these issues.

Yes. We perform pressure and flow testing on all repaired pumps, cylinders, and valves to ensure they meet OEM performance standards.

Yes. Our hydraulic repairs come with a performance guarantee, ensuring reliability and durability for an extended period.

Call us at (662) 895-5595 to discuss your hydraulic repair needs, request a quote, or schedule emergency service.

If your hydraulic system is down, Ferguson Industrial has the expertise to get you back up and running quickly. Contact us today for fast, reliable repairs.